Molybdenum Disilicide Heating Elements

Molybdenum Disilicide Heating Elements

GENERAL INFORMATION

Molybdenum Disilicide Heating Element is an electric element principally containing molybdenum disilicide for use in industrial and laboratory furnaces.?Elements fabricated of this unique material support high power densities on their surface (e.g. 20 W/cm?of element surface area at an element temperature of 1700°C, 14 W/cm?at? 1800°C and 5?W/cm?at 1900°C), can be cycled rapidly. 3 grades are available with maximum element temperatures of 1700°C, 1800°C and 1900°C in air.

Made of molybdenum disilicide based cermets MOSI2 heating elements withstand oxidation at very high temperatures. Their surface is?protected by of a thin layer of silica glass that forms when they are exposed to oxygen at elevated temperatures. Although the base cermet is consumed in the formation of the silica "skin" the rate of decomposition is minimal. They provide long performance at elevated temperatures while delivering high power.

Element resistance increases slowly over time as the cermet decomposes and the diameter of the heating shank is reduced. MOSI2 heating elements do not exhibit the rapid aging of silicon carbide or metallic iron-chrome-aluminum alloy elements.MOSI2 heating elements operate at the highest temperatures and give longest life in oxidizing atmospheres. They can operate in other atmospheres but have reduced maximum temperatures.

HARACTERISTICS & PROPERTIES

| Resistivity vs. Element Temperature for Grade 1700 and 1800 Elements | Maximum Surface Load vs. Furnace Temperature for Grade 1700 (red) and 1800 (black) Elements. |

|

|

USEFUL ELEMENT TEMPERATURES IN VARIOUS ATMOSPHERES, ? (?)

| Grade | 1700 | 1800 | 1900 |

| Air | 1700 (3092) | 1800 (3272) | 1850(3360) |

| Nitrogen | 1600 (2912) | 1700 (3092) | 1800 (3270) |

| Argon, Helium | 1600 (2912) | 1700 (3092) | 1800 (3270) |

| Hydrogen | 1100-1450 (2012-2642) | 1100-1450 (2012-2642) | 1100-1450 (2012-2642) |

| Nitrogen/Hydrogen 95/5%* | 1250-1600 (2282-2912) | 1250-1600 (2282-2912) | 1250-1600 (2282-2912) |

| Exogas (e.g. 10% CO?/SUB>, 5% CO, 15% H?/SUB>) | 1600 (2912) | 1700 (3092) | 1700 (3092) |

| Endogas (e.g. 40% H?/SUB>, 20% CO) | 1400 (2552) | 1450 (2642) | 1450 (2642) |

| Cracked and partially burnt ammonia (~8%H?/SUB> ) | 1400 (2552) | 1450 (2642) | 1400 (2552) |

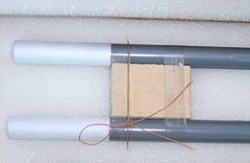

INSTALLATION AND USE

For highest temperature and power performance plus longest life MOSI2 Heating Elements? should be installed in a free hanging manner. The elements should be positioned far enough away from furnace walls to allow for their natural movement as they deflect due to relief of internal stress and bowing & twisting due to electromagnetic interaction with neighboring elements. The use of?furnace accessories including Heating Element Holders and Heating Element Straps to support and electrically connect the element terminal shanks is recommended. At low temperatures MOSI2 heating elements are brittle and should be handled with care. At temperatures above 1200? they become ductile and sag under their own weight and assume a "Coke Bottle" shape as the sections of the element's heated length repel each other.

MOSI2 Heating Elements with bent terminals can be installed through the side walls of a furnace lining. Heating Element Holders should be used to secure the terminals. When the elements are installed in a manner where they are directly supported by refractories or touch insulation, they should be installed in a manner where they are free to move. When this application method is used their maximum temperature is lowered as reactions with the silica "skin" and the development of stresses causing catastrophic failure may occur.

MOSI2 heating elements exhibit a significant positive temperature coefficient of resistivity. As the element temperature increases so does its electrical resistance.? Typically a phase angle fired SCR with current limit capability is used to control the high currents established when the element is first fired. After warming up, it's resistance increases and limits the flow of current by itself.

|

|

|

|

|

|

|

|

AVAILABILITY?

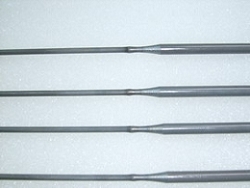

TYPICAL sizeS

| Grade | 1700 | 1800 | 1900 | |||||||||

| d/cmm | 3/6 | 4/9 | 6/12 | 9/18 | 12/24 | 3/6 | 4/9 | 6/12 | 9/18 | 12/24 | 3/6 | 6/12 |

| Le, max mm. | 350 | 450 | 1400 | 1400 | 1700 | 350 | 450 | 1400 | 1400 | 1700 | 320.0 | 360.0 |

| Lu, max mm | 300 | 450 | 1000 | 1000 | 1000 | 300 | 450 | 1000 | 1000 | 1000 | 320.0 | 360.0 |

| a typical mm | 25 | 25 | 40/50 | 60 | 80 | 25 | 25 | 40/50 | 60 | 80 | 25 | 40/50 |

| f mm | 25 | 25 | 45 | 75 | 100 | 25 | 25 | 45 | 75 | 100 | 25 | 45 |

| g mm | 15 | 15 | 25 | 30 | 40 | 15 | 15 | 25 | 30 | 40 | 15 | 25 |

STANDARD MOSI2 HEATING ELEMENTS

Standard Heating Elements are available for immediate shipment from stock.

Custom heating elements are available on request. MOSI2 Heating Elements are typically produced in an "U" shaped form, but a wide variety of sizes and shapes can be made. Straight dual shank elements are available in the types and variety of sizes listed above. Elements with metric sizes, special size diameters, such as 12/24 mm and A dimensions?are available. Special shapes such as elements with multiple shanks, bends (e.g. 90? 45? 30? etc.) in their heating and terminal sections plus flat panel and wafer heaters, can be fabricated. The techniques used to produce MOSI2 elements permit the production of an almost unlimited variety of custom element shapes and sizes. Custom shapes include, 90° bends, 45° bends, multi-shank, cylindrical and more.

sales@chinatungsten.com

sales@chinatungsten.com